05: Wind-on Leaders

Between The Lines - Ch 03: Knots and Connections

by Top Shot Tackle

|

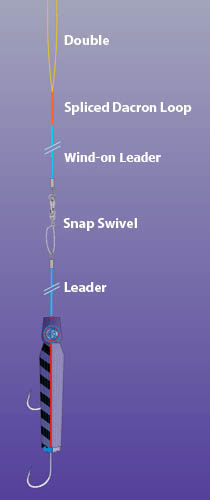

An example of a 24kg outfit using a wind-on leader is a short double say, 3-feet, connected to a 19-foot-long 200lb wind-on leader, via a spliced Dacron loop. At the other end of the wind-on, a snap swivel with a breaking strain greater than 200lb, is crimped. The lure leader is 9-feet of 300lb. Note that under IGFA rules this is measured from the end of the loop that connects to the main line to the end of the lure skirt or trailing hook, whichever is the longer. Other factors should be taken into consideration when making the decision whether to use wind-on leaders or not, some of which are: - Wind-on leaders take up a significant amount of space on the spool which means you will not be using a full spool of line. This results in a loss of speed in recovering line and a greater variance in drag setting, as the line loss will diminish spool size, increasing drag setting quicker than if you use a full spool of line. - They are dangerous if they get jammed in the reel housing. To prevent this more space on the reel spool should be allowed for them. - The leader length and thickness should be considered. A wind-on leader in some areas is considered to be as long a length of 600 or 800lb leader as possible regardless of line class, bait or lure size. If they are considered more an extension of the main line with added strength then the system will work more effectively. There are several examples following. |

||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

|

The breaking strain of the wind-ons and leaders reflects how much abrasion one could expect during a prolonged fight with a marlin using the likely drag settings for each line class. There are situations where using heavier or lighter wind-ons and leader sizes may be an advantage. Note that in all situations the connection between the wind-on and leader should be at least the breaking strain of the wind-on leader. The lengths of the double, wind-on and leader are based on the IGFA allowable lengths and also an allowance to take into consideration the lengths of the leader, which should be at least the length of the fish you expect to catch. This length allows the lure to slide away and not be used as a counterweight to help throw the lure when the fish shakes its head and/or jumps. Wind-on leaders are economical as the short leaders use much less material. Lures on shorter leaders are easier to store. The extra leader length of the wind-on allows the traceman to get hold of the leader earlier in the fight than if using shorter leaders. They can also be used by the angler in the same manner as with taking a wrap on the double as shown in the advanced angling exercises. Making a Wind-on LeaderThe following is the Top Shot Tackle method of preparing a wind-on leader. The methods and tools shown in use can also be incorporated into making topshots. 1 - Cut 2-feet of Dacron. The Dacron should not be of a greater breaking strain than the nylon used as the system is based on the Dacron expanding to fit tightly over and securely grip the nylon leader. 2 - With one end of the Dacron slightly shorter than the other, form a loop of around 1-inch using a loop needle by passing the Dacron back through itself at right angles. |

||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||

|

4 - The shorter end of the Dacron is then threaded down the middle of the longer end. The longer end is then bunched up at the loop end and held in place by a needle or safety pin. |

||||||||||||||||||||||||||||||||

|

5 - The end of the leader nylon that will be used as the wind-on is cut at an angle, also known as a rat tail, and inserted into the back of the appropriate-sized needle. The nylon is then threaded up the inside of the shorter end of the Dacron. The needle is then removed from the wind-on. The nylon end is then superglued to hold it in place and pulled back into the Dacron. |

||||||||||||||||||||||||||||||||

|

6 - The Dacron loop is then placed in the stretching jig and stretched down over the nylon by pulling with the fingers and rubbing it down, and then held in place with a drop of superglue. The longer Dacron end is now freed and also pushed and then stretched over the shorter end and the nylon is once again held place with a drop of superglue. 7 - Prior to binding the join of the Dacron and nylon, the leader is again stretched in the jig. This stretching is very important in making a secure, reliable wind-on loop splice hold under the extreme pressure of a fish striking and fighting. As with the top shot there are several possible methods. In this case the Top Shot Tackle bobbin is used with 80lb Spectra thread. A drop of superglue is once again put on the end of the Dacron and the splice is begun, ensuring the bobbin is pre-tensioned. Used in the method shown the bobbin will automatically track down the Dacron. The Bobbin bind is then finished off with a variation of half hitches and rather than end it there, another bind is done back over the top and past the first one for extra security, and once again finished with a variation of half hitches. |

||||||||||||||||||||||||||||||||

|

The splice is now complete and can be coated as with the top shot with a flexible super glue or waterproof adhesive for added protection and security. As with the previous top shot, half hitched wax thread is also a very secure method of securing the area of the Dacron to nylon join. |

||||||||||||||||||||||||||||||||

|

The wind-on leader is connected to the main line double as follows: Pass the double through the Dacron loop. Pull the leader through the double out through the top and over the outside of the double. Then back up through the middle and over the other side of the double. Pass the leader back through the middle from underneath out to the top. Snug up, moisturising the nylon as you pull the loops away from each other to tighten them.

|

||||||||||||||||||||||||||||||||

|

|

Wind-on leaders is a system where the leader is connected to the main line in a manner which allows the leader to be wound directly onto the reel spool. Using leaders of 100lb or less, knots such as the uni knot are adequate as are several other types. Leader sizes greater than this require other connection systems such as the Dacron or Spectra splice. The method of connection of the leader to the main line is a critical factor. There is a very high failure rate when this is done incorrectly.

Wind-on leaders is a system where the leader is connected to the main line in a manner which allows the leader to be wound directly onto the reel spool. Using leaders of 100lb or less, knots such as the uni knot are adequate as are several other types. Leader sizes greater than this require other connection systems such as the Dacron or Spectra splice. The method of connection of the leader to the main line is a critical factor. There is a very high failure rate when this is done incorrectly. 3 - Here we are showing how to make a Tanaka splice. The Tanaka loop holds the Dacron proud and stops the hinging that occurs without this addition. This is done by passing alternate ends of the Dacron through the other at right angles at least three times each end, that is, a total of six passes of the needle.

3 - Here we are showing how to make a Tanaka splice. The Tanaka loop holds the Dacron proud and stops the hinging that occurs without this addition. This is done by passing alternate ends of the Dacron through the other at right angles at least three times each end, that is, a total of six passes of the needle. The snap is then attached to the leader using abrasion-resistant chafing gear such as a thimble or nylon tubing. It is also important to note that a crimp wound into a tip may well damage it, so something should be used to cushion this, such as wax thread bind or a small flexible bead glued into position.

The snap is then attached to the leader using abrasion-resistant chafing gear such as a thimble or nylon tubing. It is also important to note that a crimp wound into a tip may well damage it, so something should be used to cushion this, such as wax thread bind or a small flexible bead glued into position.