Rigging Bits

by Peter Pakula

There are many considerations in rigging lures, most importantly the components, all of which go together to turn to either enhance a lure to behave as it should or wreck its action to the point you might as well tow a bit of rag. There is no doubt that on certain days in certain places the towed rag will catch fish, however, get a lure working its best and you’ll catch fish on most days in most places. Consistency is what marks success, the ability to tune not only your senses and fish finding abilities but also your equipment.

Attention to detail is important, but knowing which details need attention is most important. I hope the following makes the art of rigging and balancing a lure a little clearer.

Having the best pattern of lures rigged correctly is an important aspect of trolling, it’s a part of the whole system. However, the best set of pro rigged lures will not compensate if they are run with no regard to positioning, or finding fish with badly set outriggers and drags not set correctly.

Rigging lures is based on specifics, certain rigs work best with certain lures. The following is based on many years of trials and statistics. There is a right and a wrong way of doing everything. Unfortunately the best way of rigging lures may not be both the easiest or the simplest, but getting the peak performance in lure balance and action does improve the odds and does increase your results. Doing it right is certainly worth the extra effort and cost.

RIGGING COMPONENTS

HOOKS

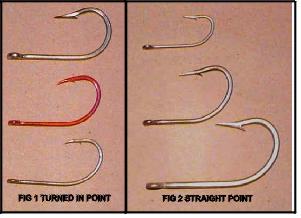

There are of course many hook shapes and sizes available. The only controlling factor is that the hook is not offset. The hooks generally used for rigging lures fall into two main categories. Turned in points, Fig 1 and straight points Fig 2.

Essentially hooks with straight points are for use in stiff rigs and the turned in points for both stiff and loose rigs. It is quite apparent that the highest hookup rates are attained by rigs using hooks that have turned in points such as the one at the top of Fig 1. This shape is commonly known as "Southern & Tuna".

It should be clearly understood that the ultimate hook for trolling lures has not yet been made. However, there are a couple that has come close, in Fig 1 the two lower hooks are the ideal shape, unfortunately, they are chemically sharpened and have a very short lifespan. The most important characteristic of these hooks is a turned in beak point. Regardless of the direction of pull this shape continues to pull in. They are also quite light and only suitable for 15kg and under, however, these hooks are light enough and sharp enough to be highly effective on line classes as light as 4kg.

Of course, all hooks should be sharpened before use. To aid penetration the barb should also be sharpened and cut down.

CHOOSING HOOK SIZE

There are a couple of considerations when choosing hooks for specific lures. The larger and heavier the gauge of the hook the  more the lure action is overridden by the rudder effect of the hooks. In some lures such as those with symmetrical head shapes, this rudder effect is part of the system. In other non-symmetrical head shapes such as sliced heads, the hooks actually interfere with lure action. As a general guide, the hook size should be so the bight of the hook is equal to the diameter

more the lure action is overridden by the rudder effect of the hooks. In some lures such as those with symmetrical head shapes, this rudder effect is part of the system. In other non-symmetrical head shapes such as sliced heads, the hooks actually interfere with lure action. As a general guide, the hook size should be so the bight of the hook is equal to the diameter

of the lure head, that is the lure head should fit through the bight of the hook as shown in Fig 3.

The result is that around 50% of the bight is available to hook the fish as shown in Fig 4.

WIRE

Though wire is rarely used as leader material it is often used as a spacer between the back of the lure head to the trailing hook. The wire generally used is stainless steel 49-strand cable. Wire is used because it will retain its set angle and lies nice and straight. The use of wire also protects this area of the rig which is most likely to come in contact with sharp teeth or abrasive jaws and bills.

LEADER MATERIAL

Originally all trolling lures were rigged on multi-strand wire cable, with the advent of nylon it was soon realized that it was far more acceptable to game fish and has been universally adopted as the best leader material to use. This is apparent with the many brands of leader material competing in the market. Every brand has its individual properties from ultra-thin, to ultra stiff, ultra supple, abrasion resistant and recently fluorocarbons. Points worth noting is the stiffer, thicker and longer the leader the more the lure has to carry. This is true of all rigging components, the more luggage the lure has to carry the less the lure is allowed to exhibit its ideal action. In a perfect world, the best possible lure action would be attained with a leader as thin and supple as a hair and as strong and abrasion resistant as a titanium RSJ.

Apart from thick leaders retarding action they are also quite visible to the fish and may create a disturbing bubble trail of their own. In all other fishing systems, it is acknowledged that one of the logical ways of increasing your catch is to lighten the leader. The lighter the leader the more bites you get. This is just as applicable to using lures as it is to all other types of fishing. This is a case of worrying so much about losing that fish of a lifetime, that very long and thick leaders are used to a point that many fish are not lost because they are spooked in the first place. A general guide is tabled below.

|

Lure Size |

Min Line Class |

Leader Size |

|

6.50" |

4kg |

100lb |

|

8.00" |

6kg |

150lb |

|

10.00" |

8kg |

200lb |

|

12.00" |

15kg |

300lb |

|

14.00" |

24kg |

400lb |

The stretch factor and elasticity of nylon leaders should be addressed. The more it has the more cushioned the jerking when the fish is traced. The downside is that if it stretches too much the leader may pull out of crimps. An otherwise legal leader may have stretched beyond the legal limit. Stretchy nylon can also cause problems if a fish surges when a leader man has multiple wraps around a gloved hand as the nylon may cut in and bind on the glove making it difficult to dump the wraps.

LEADER LENGTH

The types of lures discussed here are skirted trolling lures. One of the main characteristics of these types of lures is that they are designed to slide away from the fish on hook up. This is because many of the species, particularly Marlin and Mahi Mahi are very athletic, spectacular jumpers and head shakers. If the hooks were fixed to the lure head their weight and resistance would act like a pendulum resulting in many thrown hooks and lost fish. This consideration would suggest a minimum length so that the head shaking and jumping does not result in using the weight of the lure to throw the hooks. This minimum length would be around 8’. Ideally, the connection of the leader to double, usually a snap swivel should not continually splash and bubble on the surface which is hard to avoid on leaders shorter than 8 feet.

Long leaders up to 30 feet on medium and heavy tackle are generally used by experienced crews to compensate for novice anglers. As expected, short leaders of around 9 to 12 feet are used by experienced anglers fishing with novice crews and skippers. Shorter leaders are also used in solo game fishing.

The benefits of short leaders are that as discussed before, the less the weight the lure has to carry the better the lure action, plus they enable tagging or gaffing directly off the rod tip. Many tournament winning fish have been lost as the trace man grabs the leader and pulls the hooks out of the fish before a tag or gaff could be put in.

WIND ON LEADERS

Though wind on leaders have been around for many years there has been a recent resurgence which raises some discussion. Winds on leaders were primarily introduced by commercial charter operations so that they could pack lots of rigged baits in their freezers without the leaders tangling. Plus these short rigs of only around 3’ saved a great deal of money through a busy season.

Wind on leaders were also found safer when heavy tackle fishing as the leader was safely stored on the reel rather than washing around and tangling in an often water-filled cockpit or whipping around the trace man's head. The use of this system has also been adopted by single crew charter operations as the deckhand can cope with pulling on the fish and tagging or gaffing it without assistance.

Clearly, the wind on leaders have a purpose. However, in lure trolliing, they have some major disadvantages.

- The leader from the lure to the snap is generally too short with an increased incidence the fish throwing hooks.

- The snaps consistently splash on the surface, which can often be responsible for spooking fish.

- The added weight of the leader which is generally of maximum length and thickness is far too much luggage for the lure and retards its action so that it is quite simply not as effective as it should be.

The result with wind on leaders is quite simply less fish lost because there are fewer strikes.

If the system appeals then try using a short leader of around 9 to 12 feet, with a long double say 25 feet on medium tackle. If more pressure is needed on the fish as it gets close to the boat the angler can put as much pressure as they wish as soon as the reel has a couple of turns of the double on it.

CHOICE OF LEADER

As with all choices in fishing tackle everything is a compromise. There is no doubt that many of the species hunted using trolling lures have very rough jaws, skin and bills that demands abrasion resistant leaders. Many of these animals are huge creatures that require as much strength and reliability as possible in the tackle and leaders. Just as clearly these large predators, at the top of the food chain, are certainly not less cunning or less intelligent than the smaller species we fish for using gossamer thread and well presented baits in an effort to catch as many or as large a fish as possible.

CRIMPS

Crimps also known as swages have taken over from using knots in lure rigging essentially because it is quicker and easier to line up and center the components.

There are two main types, which have different methods of crimping:

1) Crimps for multi strand wire are generally binocular or figure 8 crimps, as in Fig 5, are twin barrelled and generally made of coated copper. The way this system works is that the crimp is softer than the wire and when crimped the wire filaments indent the inside surface of the crimp resulting in a very strong connection. When crimping wire the crimp is swaged along the full length of the crimp. To tighten the loop when using chaffing gear such as thimbles start crimping from the end of the crimp away from the thimble and work up the crimp to towards the thimble.

way this system works is that the crimp is softer than the wire and when crimped the wire filaments indent the inside surface of the crimp resulting in a very strong connection. When crimping wire the crimp is swaged along the full length of the crimp. To tighten the loop when using chaffing gear such as thimbles start crimping from the end of the crimp away from the thimble and work up the crimp to towards the thimble.

2) Crimps for nylon are generally oval shaped aluminum as in Fig 6. Unlike crimping wire the system works by the crimp crushing both the crimp and the nylon. For this reason, the crimps used on nylon are usually considerably longer than those used to connect wire as they are based on friction. When crimping nylon the ends of the crimp are left flared so that the ends don’t cut into the nylon.

When crimping nylon the ends of the crimp are left flared so that the ends don’t cut into the nylon.

The following points are applicable to successful crimping both wire and nylon. Most importantly the crimp should be the correct size. It should be a snug fit. This can only be achieved if the ends of the material are cut neatly which involves using the correct tools. Cutting tools such as the parrot jawed Felco are perfect for wire. Anvil garden shears do a great job of precisely cutting nylon.

Dedicated swaging pliers with double hinged jaws such as the Jinkai in Fig 7 are a must. There are many brands available. This is certainly a case of you getting what you pay for. The wider the jaws and the heavier the pliers the better. Several of the larger types have also got pressure adjustments. Nearly all leader manufacturers have a swaging system that incorporates leaders, crimps and pliers and instructions so that the correct components are used as well as the correct crimping position on the pliers is used.

Dedicated swaging pliers with double hinged jaws such as the Jinkai in Fig 7 are a must. There are many brands available. This is certainly a case of you getting what you pay for. The wider the jaws and the heavier the pliers the better. Several of the larger types have also got pressure adjustments. Nearly all leader manufacturers have a swaging system that incorporates leaders, crimps and pliers and instructions so that the correct components are used as well as the correct crimping position on the pliers is used.

Correct positioning of the crimp in the pliers’ jaws is very important. The swage should be positioned as in Fig 8 with the oval shape of the crimp vertical.

CHAFFING GEAR

Wear and tare on leader, rigs and the lures themselves occur just from being used. All lures have some type of action if only from the influence of sea conditions and the configuration of the boat wash. This action and movement of the components causes abrasion and wear through friction. Nylon leaders in particular are easily abraded and weakened by friction. On all parts of a rig where the leader comes into contact with any other part that is free to move against it, we use protective items such as thimbles, nylon tubing, wire or stainless springs as shown in Fig 9. All of these items are known as chaffing gear. In many cases, we secure parts of the rig with heat shrink tubing or rigging tape or coloured electrical tape.

Nylon leaders in particular are easily abraded and weakened by friction. On all parts of a rig where the leader comes into contact with any other part that is free to move against it, we use protective items such as thimbles, nylon tubing, wire or stainless springs as shown in Fig 9. All of these items are known as chaffing gear. In many cases, we secure parts of the rig with heat shrink tubing or rigging tape or coloured electrical tape.

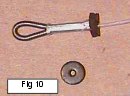

One of the main and often overlooked areas of wear is at the point where the back of the lure head rests against a crimp. A leader on an active lure can very quickly fatigue and break. This is often wrongly blamed on toothy fish such as mackerel, wahoo and sharks. Inserting a rubber washer between the back of the lure head and the crimp easily solves this as shown in Fig 10.

Thimbles are often used to protect leaders where they connect to hooks, snaps, and shackles. However, they are often used incorrectly. Thimbles are often supplied with open jaws so they may be passed through hook eyes or rings as shown at the top of Fig 11. Before crimping the thimble jaws should be closed with a pair of pliers as shown at the bottom of Fig 11.

Thimbles are often used to protect leaders where they connect to hooks, snaps, and shackles. However, they are often used incorrectly. Thimbles are often supplied with open jaws so they may be passed through hook eyes or rings as shown at the top of Fig 11. Before crimping the thimble jaws should be closed with a pair of pliers as shown at the bottom of Fig 11. If the thimble jaws are left open the thimble can twist in the nylon loop and easily cut through it.

If the thimble jaws are left open the thimble can twist in the nylon loop and easily cut through it.

It is important that any tubing, thimbles or springs that are used should fit the leader as tightly as possible and that the crimp should be snugged up so there is no leader exposed at the ends.

SHRINK TUBING AND RIGGING TAPE

Electrical shrink tubing, Fig 9 and electrical tape are often used to protect joints, align components and stiffen rigging. Both come in a good selection of colours that can also be used to highlight rigs and imitate baitfish lateral lines.

SHACKLES

Small stainless steel yachting shackles Fig 9 are a great way of a very strong (minimum 500lbs) quick connection between leaders and hooks. Particularly useful for loose free-swinging rigs as they allow a great amount of freedom of action and movement.